OTHER SOLUTIONS

General Kinematics has a long history of applying vibratory science to unique applications. Here are even more equipment solutions utilized by No-Bake Foundries around the world.

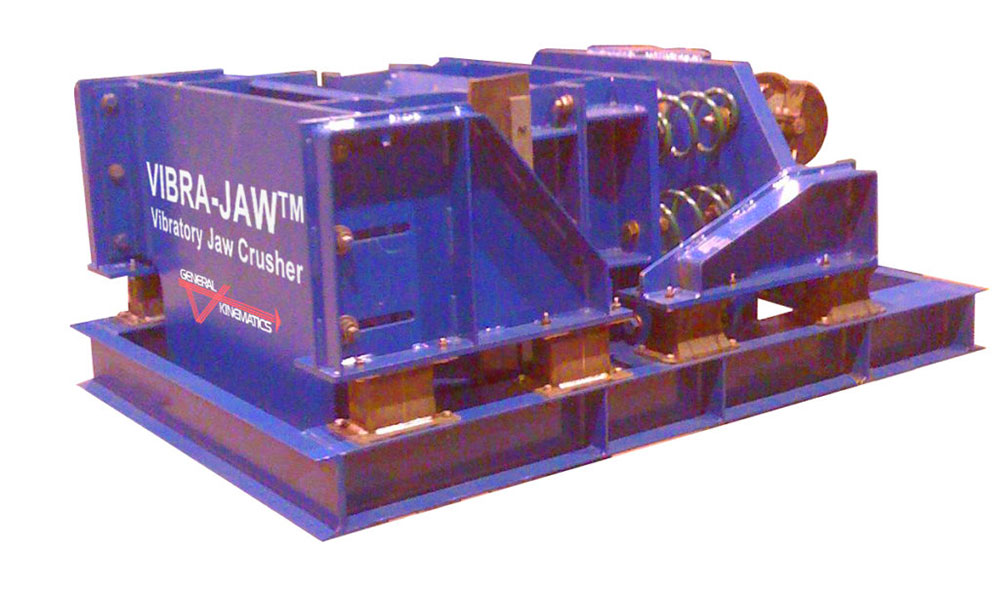

VIBRA-JAW™ VIBRATORY JAW CRUSHERS

General Kinematics VIBRA-JAW™ Vibratory Jaw Crusher uses high energy vibration to rapidly reduce materials into smaller particle sizes. Vertical impact surface is easily adjustable to fine tune throughput size, and self relieving impact plate reduces jam-ups and downtime. Utilizing GK’s Two-Mass Technology, units use very minimal energy, reducing your electric consumption and utility expenses.

FEATURES:VIBRA-JAW™ is easy to service, with few moving parts.

Two-Mass drive is energy efficient and easy to maintain.

Impact area is easy to adjust, and high wear impact plates are easy to replace.

Custom engineered to your material and throughput requirements.

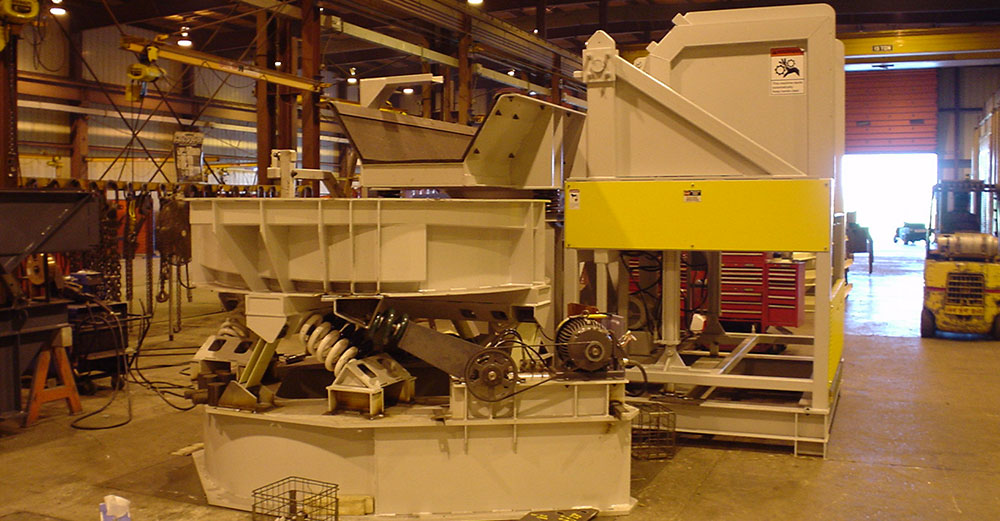

BILLET FEEDER FOR INDUCTION SYSTEMS

General Kinematics Bowl Feeding Systems can receive a batch of billets, weigh and meter them into a circular alignment bowl. Billets are aligned and fed into your continuous induction heating system. The vibratory motion allows the billets to orientate.

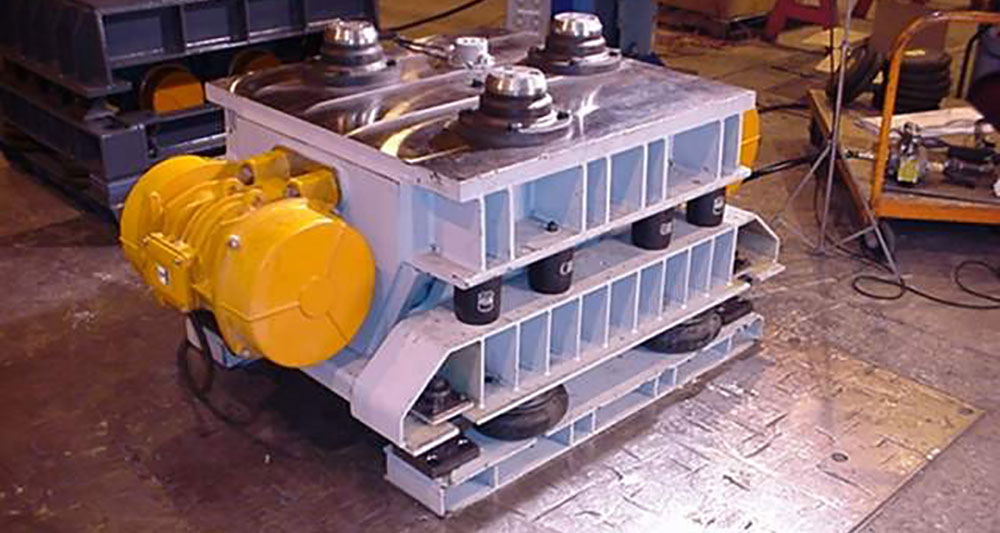

COMPACTION TABLES

Lost foam and no bake molding techniques demand superior mold compaction in order to develop casting integrity and maintain profitable production.

General Kinematics compaction tables fluidize sand to obtain optimum sand migration around all pattern surfaces, an important advantage in polystyrene processes involving intricate shapes.

Sand is compacted to maximum density and hardness, producing close tolerance castings with good surface finish. Quality is improved, with less scrap and lower unit costs.

Flask clamping eliminated

The stable, three-point flask support has unique, contoured, sound deadening flask fixtures which precisely locate and secure flask during compaction cycle. Separate clamping devices are eliminated, speeding production and eliminating maintenance.Programmed operation

Computerized, variable control is programmed for the vibratory action needed for each specific pattern. As flask fills, integrated feedback automatically compensates for increasing sand weight to sustain desired vibration intensity. FEATURES:The stable, three-point flask support has unique, contoured, sound deadening flask fixtures which precisely locate and secure flask during compaction cycle. Separate clamping devices are eliminated, speeding production and eliminating maintenance.

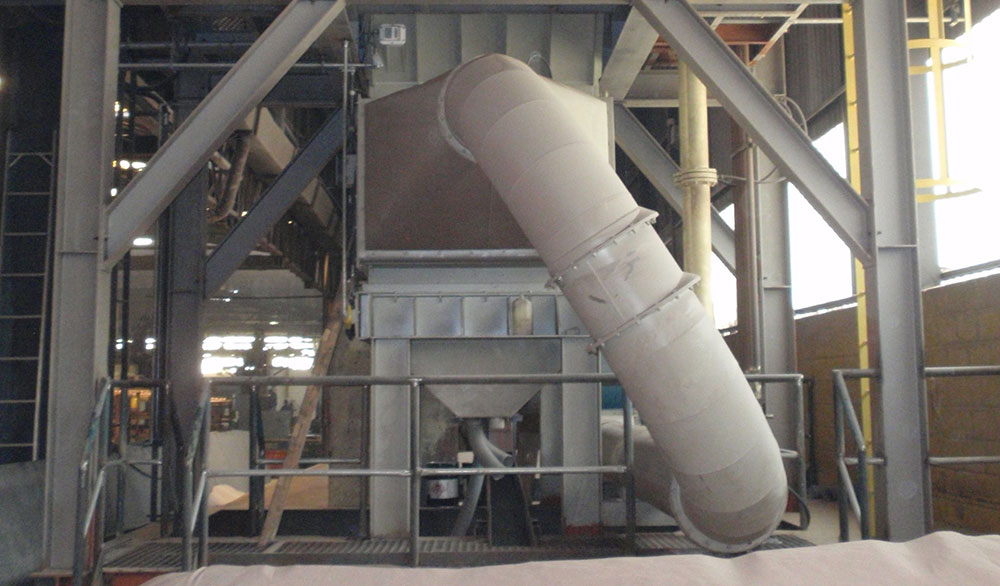

SAND CLASSIFIERS

General Kinematics sand classifiers sort sand by grain size. Classifiers separate sand by grades, remove dust, and discard waste sand. The remaining “good” sand is distributed by grain size, then can be discharged to be remixed into the AFS required for your process. Air flow is recirculated, reducing bag house requirements.

FEATURES:Classifies granular materials based on size and density.

Provides a product distribution from a metered flow.

Multiple discharges allows for product to be re-mixed into whatever AFS required.

Heavies and lights can be removed from the material stream.

Air is recirculated, requiring minimal bag house or permitting.

Can be paired with Sand Cooling and screening.

VIBRA-LIFT™ VIBRATORY ELEVATOR

General Kinematics VIBRA-LIFT™ vibratory elevator transports granular material vertically in an easy to use, low maintenance vibratory device. With product flow up to 8 tph, the VIBRA-LIFT™ can elevate your flowable solid product to gain elevation height in your process. Units are ideal for material that exceed the recommended temperatures of traditional bucket elevators.

FEATURES:Elevates hot or difficult to handle product

Simple design is easy to maintain

Works well in combination with GK’s VIBRA-MILL® sand reclaimers.