SCREENING SOLUTIONS

From de-watering sand to separating boulders, GK has a vibrating screen perfect for your process. GK’s brute force and two-mass screening solutions are designed to maximize uptime and throughput. With our STM-Series Two-Mass screens, customers are seeing their throughput improve by up to a factor of two, all while fitting in the same footprint and using 2/3rds less energy.CHECK OUT OUR FULL LINE OF SCREENING SOLUTIONS:

FINGER-SCREEN™ Grizzly Screens

General Kinematics non-blinding FINGER-SCREEN™ Grizzly Screens are a proven, highly successful design in a wide range of applications, including those that are prone to hang-ups common to conventional wire mesh screening surfaces.

GK’s “mine-duty” design means you are buying a screen that will last. Heavy construction, combined with our two-mass drive technology, allows for a super strong and efficient vibratory screen that will keep running and running. Combining that with our non-blinding FINGER-SCREEN technology gives you the ultimate in screening throughput and efficiency.

FINGER-SCREENS are available in single or multiple deck designs and can be designed to fit into your existing machines footprint for a seamless transition from old brute force technology to the improved two-mass design.

FINGER-DECKS offer a non-blinding design compared to wire mesh screens.

Optional cascading decks improve screening efficiency.

Modular decks are easy to replace.

Using a single vibratory motor, there is virtually no maintenance required.

Will fit into your existing footprint.

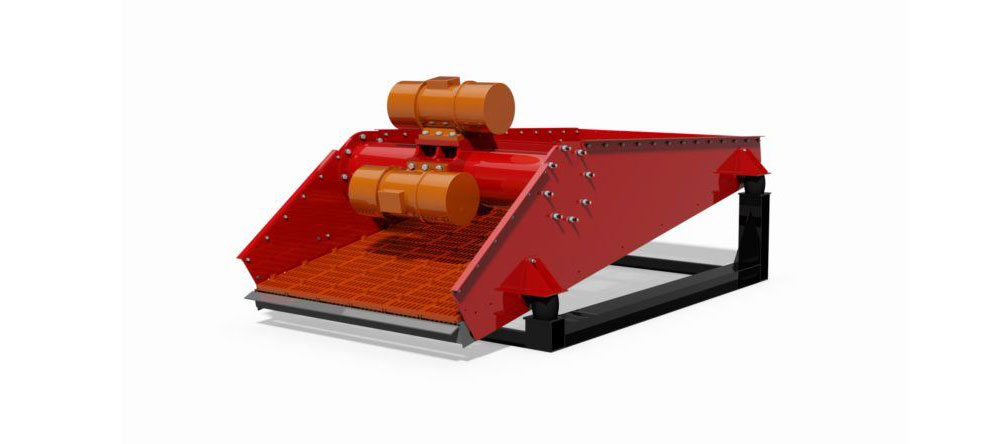

STM-SCREEN™ Two-Mass Vibratory Screens

General Kinematics STM-SCREEN™ Two-Mass Vibratory Screens utilize GK’s proven Two-Mass, natural frequency drive design. This design is load responsive and capable of longer material retention times to work the material more. This means you can get more screening accomplished in the same footprint as your old brute force screens.

Dual in-board vibratory motors eliminate expensive belts, shafts, and bearings. Our patented modular design uses a center spline to significantly increase structural integrity, and allows for easy assembly and disassembly for quick transport and installation.

All these features combine to provide increased uptime, longer service intervals, significantly increased throughput, and the lowest cost of ownership available in a vibrating screen package.

Machines are load responsive, which means that the more material they see, the harder they work.

Load responsiveness allows for a horizontal installation, significantly increasing retention times for better screening.

Heavy-duty,low-stress design lasts up to 5 times longer than traditional brute force screens.

Available with most styles and deck system configurations.

DIRECT DRIVE VIBRATING SCREENS

General Kinematics DS and VS direct drive screens offer versatility and high-performance screening in a small, value engineered package. Screens are available in a single motor design for elliptical motion or a dual motor design for linear screening. Each style comes in standard sizes, but can be customized with different deck systems, including wire mesh, steel, rod decks or polyurethane panels.

FEATURES:Equipped with either an elliptical or linear drive, depending on your process.

Heavy-duty, low maintenance design maximizes uptime performance.

Available with most deck styles and systems.

Available in quick ship standard sizes. Custom designs also available.

AGGREGATE SCREENS

General Kinematics aggregate screens are a high performance, low maintenance solution to screening of bulk aggregate materials. Single, double, and triple deck configurations allow for the ultimate in process flexibility.

Units are available with a single shaft elliptical drive or dual shaft linear drive. Both drive designs are easy to service and even easier to maintain. Heavy-duty construction means you can focus on processing material, not repairing your screen. Machines are available in industry standard sizes and can be designed to fit your existing footprint and structure.

Equipped with either an elliptical or linear drive, depending on your process.

Heavy-duty, low maintenance design maximizes uptime performance.

Available with most deck styles and systems.

Available in quick ship standard sizes. Custom designs also available.