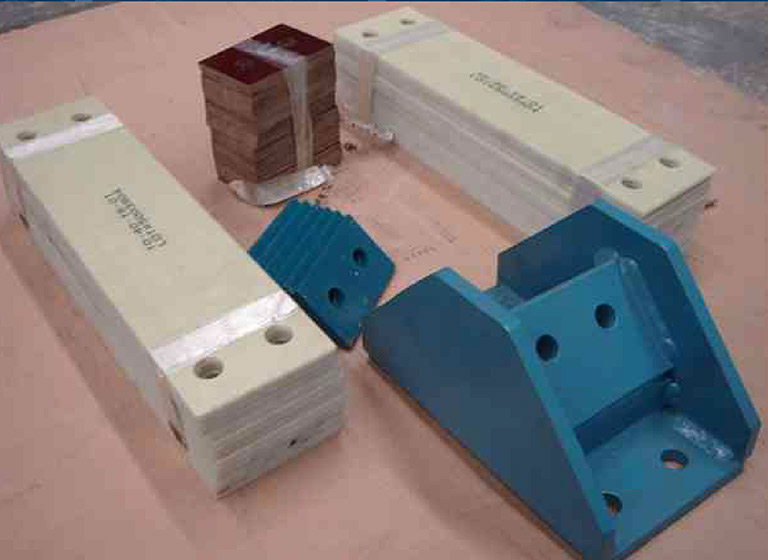

General Kinematics Plastic / Scotchply / Fiberglass / Steel Slats

General Kinematics custom made plastic, scotchply, fiberglass, or steel slats help guide your vibratory machine while providing the vibrating spring rate required to move your machine. Slats are custom engineered for your application, and can be supplied as a stand alone slat or as an entire kit including hardware and spacers.

General Kinematics can custom cut slats to your machine dimensions and requirements, no matter what brand of vibratory equipment you might have. Contact GK for more information about replacement shaker slats for vibratory equipment.

VELOCITROL CONTROLLER AND MONITOR

The Velocitrol is a complete system used to detect, display and control the velocity of vibratory equipment. This system consists of an industrial accelerometer, a pair of Vibration Transmitters, and the computer based display and control unit.

The Velocitrol is a PLC based controller that receives signals from two Vibration Transmitters. The Velocitrol displays the current velocity and adjusts a 4-20mA signal to a variable frequency drive to maintain a constant velocity.

The Velocitrol is capable of alternating between two velocity setpoints, which can be triggered by adjustable internal timers or by an external dry contact closure. The Velocitrol displays the stroke continuously, and monitors the stroke for under or over limits.

If either of the limits are exceeded for an adjustable time period, then the Stroke Monitor will indicate an Alarm. The Alarms can be tied to existing control equipment by the dry contact relays. All set points can be adjusted using the operator interface on the front of the Velocitrol.

Variable Force (VF) Wheels

General Kinematics exclusive Variable Force (VF) Wheels enable infinitely variable feed rates, providing up to 100% turn down. This is accomplished by varying the drive exciting force by instantaneously changing the pneumatically controlled counterweights inside. The V-F control permits “stop and resume” feed, even at minimum rates. They respond accurately to belt scales, load cells, or other feed back signals for precise proportional feed control.

General Kinematics V-F Wheels are mounted on our special vibratory motors using a double extended shaft. Our V-F Wheels require an 80 PSI air supply to control them. Because they utilize a closed end system, they do not consume air. You can estimate 1 CFM requirement per Activator Feeder.

V-F Wheels can be controlled either pneumatically or by hydraulics. Both systems are offered in either our manually operated pneumatic control box, or via hydraulic pump and our automatic electro-pneumatic or hydraulic control system. Our automatic systems are designed to receive a 4-20 MADC signal, from a remote location, and converts it to a 0 to 80 PSI air or hydraulic supply to the V-F Wheels, via customer’s PLC, working in conjunction with a belt scale down stream.

GK VSR Double C-Face Shaker Motors

General Kinematics’ Vibratory Service Rated (VSR) Double C-Face Shaker Motors are designed to withstand the substantial G-Forces of Two-Mass vibratory equipment, which are much greater than found in typical brute force vibrating applications.

This latest generation of GK’s VSR vibratory shaker motors are an evolution of 50 years of experience in designing vibratory equipment and components to survive in the toughest applications. Significant advances in engineering, tooling, life-cycle testing, and technology have resulted in the most reliable shaker motor available for vibratory applications.

Features:

• Internal / External Corrosion resistant epoxy coating for severe-duty operation in the most difficult vibrating environments.

• Special alloy castings to withstand extreme G-forces produced in Two-Mass vibratory equipment

• Rapid RPM ramp up capabilities for reliable and consistent startup.

Contact GK’s Component Part Specialists for more information on these motors, repairs, and maintenance.