MATERIAL HANDLING

Versatile vibratory equipment from General Kinematics does more than just move materials. The inherent motion of continuously tossing and throwing material forward creates the opportunity to perform one or more processes along the way. Depending upon your application, GK equipment can be engineered and constructed with custom designs to handle hot, heavy, and/or abrasive materials in the foundry, including sand, sprue, castings, and dross.

VIBRATORY CONVEYORS FOR FOUNDRY APPLICATIONS

CONVEYORS DESIGNED FOR ANYTHING YOU CAN THROW AT THEM.

Are you going to push a glowing red casting onto a rubber belt? No. How about hot flowing sand onto an apron or metal belt conveyor? Only if you like to sweep. Only one technology meets the demanding environment of a hot and abrasive foundry, and that is vibratory conveyors from General Kinematics.MORE THAN JUST CONVEYING

Versatile vibratory conveyors from General Kinematics do more than just move materials. The inherent motion of continuously tossing and throwing material forward creates the opportunity to perform one or more processes along the way. Depending upon your application, conveyors can be engineered and constructed with custom trough designs to handle hot, heavy, and/or abrasive materials in the foundry, including sand, sprue, castings, and dross. Conveyors can be constructed using a variety of materials, including mild or abrasion resistant steel, stainless steel, or special alloys. Special patterns, perforations, and trough thickness can also be specified to meet your application needs.GK VIBRATORY CONVEYOR BENEFITS:

1. SUPER-DUTY DESIGN

The super duty design of GK vibratory conveyors allows them to excel in foundry applications with very little maintenance and downtime. Should something need replacing, parts are easy to replace and available from GK’s Parts team.

2. EFFICIENT DRIVE SYSTEM

Conveyors with GK’s SYNCRO-CUSHION™ coil spring drive require less horsepower to start the machine. Less horsepower required means a smaller motor, and a smaller motor means less electrical consumption and more energy savings.

3. MINIMAL ENERGY USE

GK Conveyors are designed using the principle of natural frequency. This design technique uses the harmonics of the machine to store and release energy through the spring system. That means, once the machine is running, it requires almost no energy to operate.

SPIRA-FLOW™ SPIRAL CONVEYORS

General Kinematics vibrating SPIRA-FLOW™ Spiral Conveyors offer unmatched performance with added process features. Available in infinite lengths and heights, GK Spiral Conveyors are custom built for your specific application.

Technically advanced vibrating spiral conveyors do more than just move your product. Spirals can be equipped for direct or indirect drying, direct or indirect cooling, coating, and can be designed to convey material up or down. Available in stainless or mild steel, open or enclosed, there is no limit to what a GK spiral can do.

Foundry applications include: sand, small castings, shot, sprue, cores, media, and more.

ariable Force drive allows for easy adjustment of speed and retention time.

Spirals can have open flighting or be totally enclosed, depending on your product and environmental requirements.

Optional processing features such as heating, cooling, drying, coating, and more, allow for multiple material processing in one compact machine.

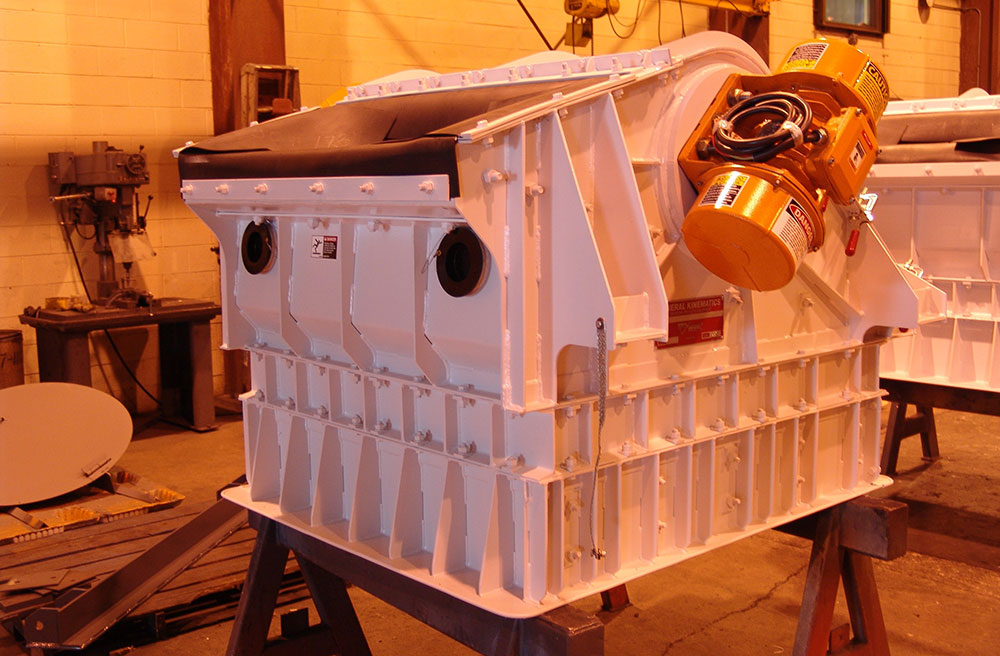

VIBRATORY FOUNDRY SCREENS

General Kinematics Vibratory Foundry Screens are unequaled in efficiency and performance in a foundry application. GK’s proven two-mass drive system reduces electrical consumption and increases screening efficiency over traditional direct drive (brute force) designs. Options include replaceable decks, multiple decked units, banana style decks, and special corrosion resistant finishes. GK Vibratory Foundry Screens are available in standard and custom sizes to easily fit into existing processes.

FEATURES:Two-mass design achieves up to 5 times electrical savings over typical direct drive screens (150 HP compared to GK’s 30 HP).

GK Two-Mass Screens are load responsive. The higher the tonnages, the higher the screening efficiencies.

Two-mass design maintains stroke level, while brute force loses stroke as more material is added.

The GK Two-Mass screen is “plug and play.” Simply plug it in and you are up and running.

Compact, low HP vibratory motors are mounted to the unit for fast change-outs.

SAND CLASSIFIERS

General Kinematics sand classifiers sort sand by grain size. Classifiers separate sand by grades, remove dust, and discard waste sand. The remaining “good” sand is distributed by grain size, then can be discharged to be remixed into the AFS required for your process. Air flow is recirculated, reducing bag house requirements.

FEATURES:

Classifies granular materials based on size and density.

Provides a product distribution from a metered flow.

Multiple discharges allows for product to be re-mixed into whatever AFS required.

Heavies and lights can be removed from the material stream.

Air is recirculated, requiring minimal bag house or permitting.

Can be paired with Sand Cooling and screening.

HULA-HOPPER® BIN ACTIVATOR / FEEDER

The General Kinematics HULA-HOPPER® Bin Activator is an improved vibratory equipment concept based on operating principles proven in thousands of General Kinematics installations. Within a single, extremely low headroom unit, the HULA-HOPPER® combines material activation, infinitely variable flow rate control, and positive flow shut-off all into one bin activator unit; yet installation, service, and operating costs are dramatically lower than for comparable bin activator systems.

HULA-HOPPER® Bin Activator eliminates many problems associated with more complex, brute force vibratory machinery because of its simplified operating design. As a Two-Mass vibratory unit, the HULA-HOPPER® Bin Activator uses a low-horsepower motor drive, therefore electric power needs are minimal. Orbital action eliminates compacting and bridging because only material drawn out is activated.

Infinitely adjustable flow control using GK’s VF wheels or electronic VFD.

Extremely low headroom design reduces bin activator height requirements.

Easy to service design.

VIBRA-LIFT™ VIBRATORY ELEVATOR

General Kinematics VIBRA-LIFT™ vibratory elevator transports granular material vertically in an easy to use, low maintenance vibratory device. With product flow up to 8 tph, the VIBRA-LIFT™ can elevate your flowable solid product to gain elevation height in your process. Units are ideal for material that exceed the recommended temperatures of traditional bucket elevators.

FEATURES:Elevates hot or difficult to handle product

Simple design is easy to maintain

Works well in combination with GK’s VIBRA-MILL® sand reclaimers.